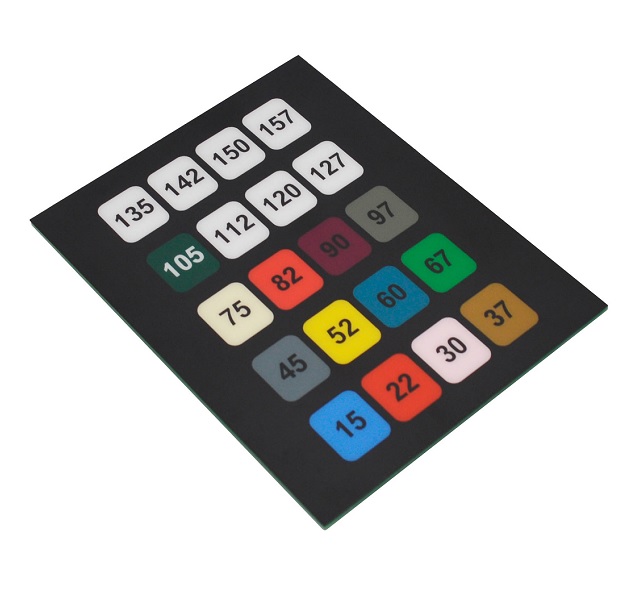

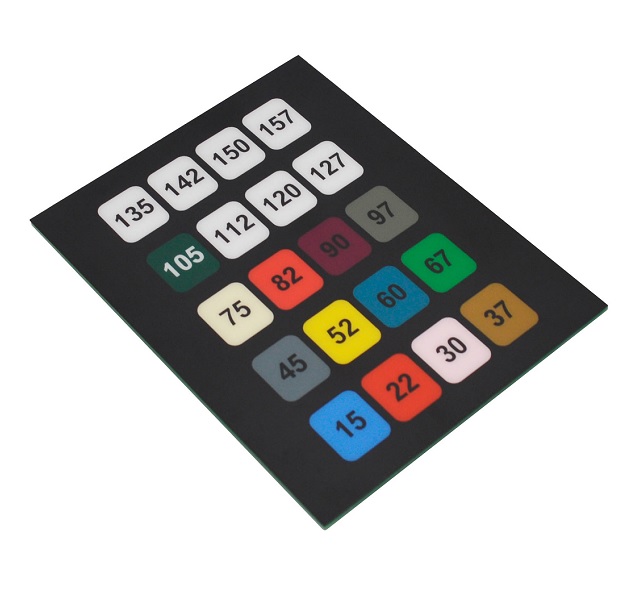

LuphiTouch's PCB Membrane Switch Membrane Keypad Introduction

For the PCB membrane switch or membrane keypad, as the name showed, its circuit will be PCB, rigid printed circuit board. The main raw materials for rigid PCB are usually FR4 and copper. It usually showed front our eyes by green color and sometimes also have red, yellow, dark blue or black ones etc.

Rigid Printed Circuit Board Spec.:

Product: Single-side, Double-sided, Multilayers. For membrane switches, the common used are single side and doubel sided;

Raw Material: FR4, CEM-1, CEM-3, Epoxy Resin CCL, isola etc.

Board Thickness: 0.16~3.0mm. For membrane switches common used are 0.6/0.8/1.0/1.6mm;

Copper Thickness: 18μm /35μm /70μm;

Process Capability: HASL, Ni/Au Plating, Immersion Silver, ENIG;

Min. Trace Width: 0.10mm;

Min. Wire Spacing: 0.10mm;

Min. Drilling Diameter: Φ0.20mm;

When and where should use rigid PCB circuit for the membrane switch?

For many of our customers who are not very familary with the membrane switch tehnology, so most of time they don't know how to select proper circuit layer for the membrane switch used on their device.

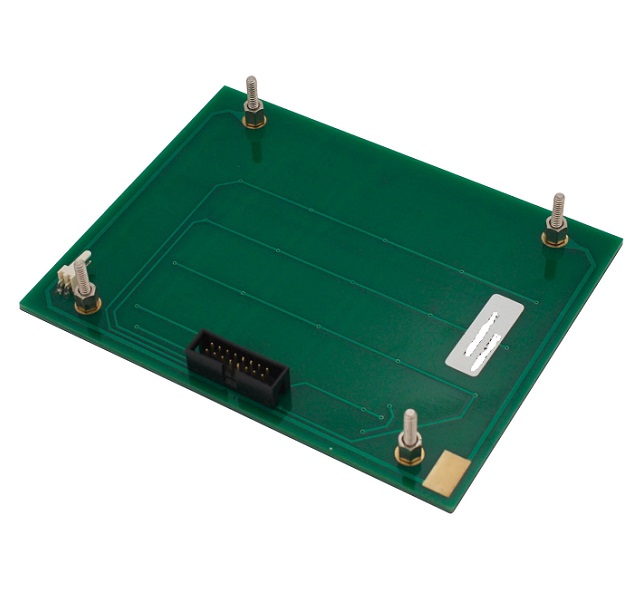

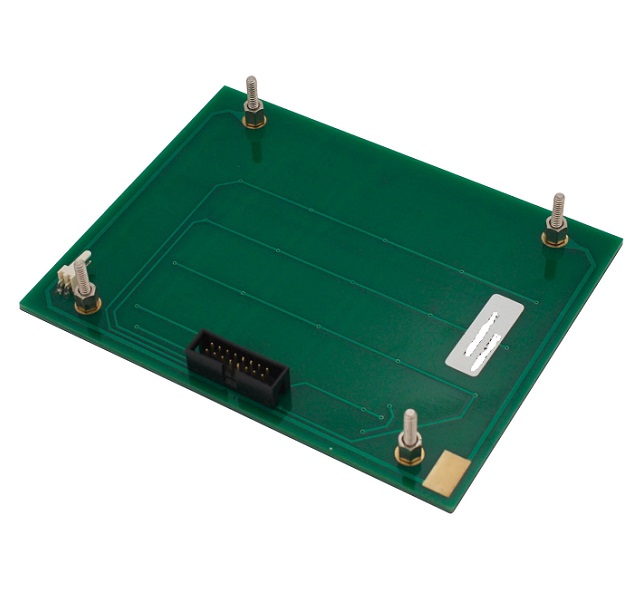

As we know, the circuit layer for membrane switch can be silver printed PET, rigid PCB and polymide FPC. If the end device used in very harsh environment, like wet, salty environments, or directly used outdoor, and the membrane switch must have a good supportive feature, then the rigid PCB circuit is a solid choice. In addition, for some special application which also need use PCB circuit for the membrane switches. Like aerospace, marine, medical etc. Because of that the PCB's material materials are copper and FR4 which is very solid and reliable and due to it is rigid which also can provide supportive performance. By the way, sometimes the membrane switch need be fixed on the equipments or machines by screws, BOLTs and NUTs. Then we can drill assembly holes on PCB and assemble BOLTs/NUTs on it.

the end device used in very harsh environment, like wet, salty environments, or directly used outdoor, and the membrane switch must have a good supportive feature, then the rigid PCB circuit is a solid choice. In addition, for some special application which also need use PCB circuit for the membrane switches. Like aerospace, marine, medical etc. Because of that the PCB's material materials are copper and FR4 which is very solid and reliable and due to it is rigid which also can provide supportive performance. By the way, sometimes the membrane switch need be fixed on the equipments or machines by screws, BOLTs and NUTs. Then we can drill assembly holes on PCB and assemble BOLTs/NUTs on it.

LuphiTouch has many years experiences of manufacturing membrane switches with PCB circuit and also with BOLTs/NUTs assembled for overseas customers like from north America, Europe etc. countries and areas. All of our products are Rohs and Reach compliance. Our factory also certified by ISO9001, ISO13485, ISO14001 and ISO45001. We have advanced manufacturing machines, testing equipments, skillful workers. All of our products are 100% function tested before the shipment.

Customize your PCB membrane switches now or

consult us more technique questions,

please feel free to CONTACT US!

the end device used in very harsh environment, like wet, salty environments, or directly used outdoor, and the membrane switch must have a good supportive feature, then the rigid PCB circuit is a solid choice. In addition, for some special application which also need use PCB circuit for the membrane switches. Like aerospace, marine, medical etc. Because of that the PCB's material materials are copper and FR4 which is very solid and reliable and due to it is rigid which also can provide supportive performance. By the way, sometimes the membrane switch need be fixed on the equipments or machines by screws, BOLTs and NUTs. Then we can drill assembly holes on PCB and assemble BOLTs/NUTs on it.

the end device used in very harsh environment, like wet, salty environments, or directly used outdoor, and the membrane switch must have a good supportive feature, then the rigid PCB circuit is a solid choice. In addition, for some special application which also need use PCB circuit for the membrane switches. Like aerospace, marine, medical etc. Because of that the PCB's material materials are copper and FR4 which is very solid and reliable and due to it is rigid which also can provide supportive performance. By the way, sometimes the membrane switch need be fixed on the equipments or machines by screws, BOLTs and NUTs. Then we can drill assembly holes on PCB and assemble BOLTs/NUTs on it.