- Membrane Switches

- PCB Membrane Switches

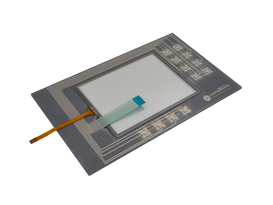

- FPC Membrane Switches

- Rubber Keypad Switches

- Capacitive Membrane Switches

- Waterproof Membrane Switches

- UV-Resistant Membrane Switches

- Medical Membrane Switches

- Backlighting Membrane Switches

- Backpanel Membrane Keypads

- Super Big Size Membrane Switches

- Silicone Rubber Keypads

- Graphic Overlays

- OCA Lamination Keypads Services

- Dome Arrays

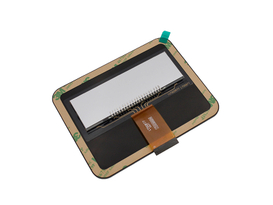

- Displays

- Parts

- Total Solutions

- Home

- Products

- About Us

- Markets

- News

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search