Views: 0 Author: luphitouch Publish Time: 2024-12-14 Origin: https://www.luphitouch.com

The factory spans 4,500 square meters, with a team of over 80 skilled workers. It is certified by ISO9001, ISO13485, ISO14001, and ISO45001. LuphiTouch® specializes in developing and manufacturing various human-machine interface switch panels, keypads, and modules. Their capabilities include:

They offer a one-stop total solutions service for clients.

In addition to membrane switch production, LuphiTouch provides:

Circuit board manufacturing

Components sourcing

SMT & PTH assembly

EMS (Electronics Manufacturing Services) contract manufacturing

LuphiTouch uses high-quality imported materials, such as:

3M double-sided adhesives

Autotype PET

Nickomatic connectors

Kingbright LEDs

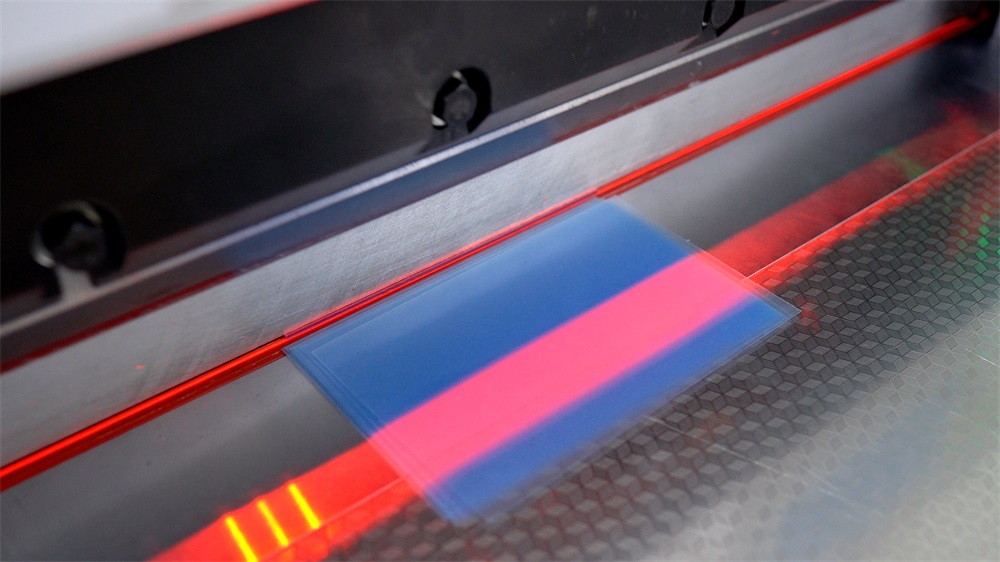

Materials like films and adhesives are cut using high-precision automatic cutting machines.

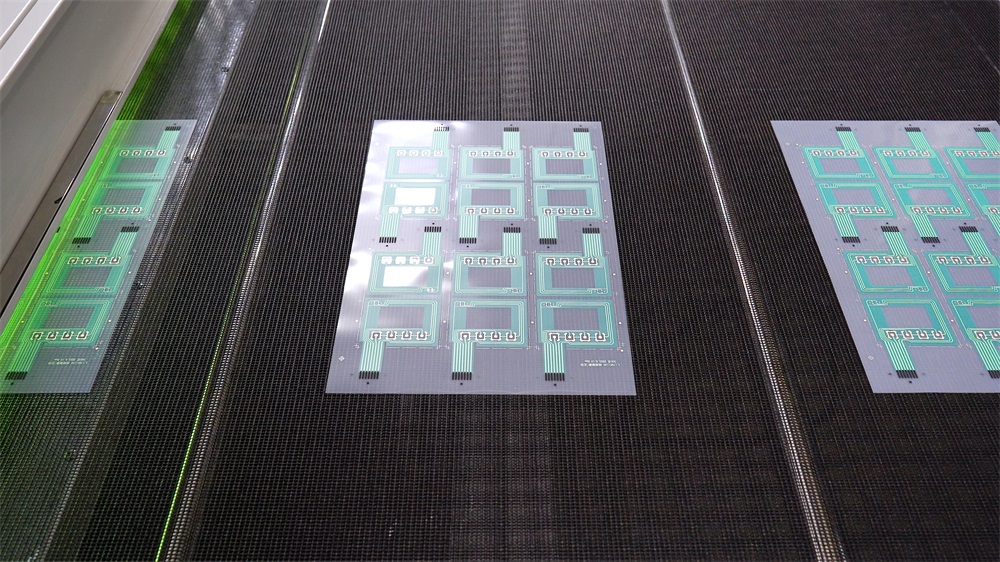

Graphic designs and texts are printed based on customer drawings, using semi-automatic screen printing machines.

The factory is equipped with:

Fully automatic printing lines

Digital color printers

These ensure accuracy and efficiency in printing processes.

Printed graphic overlays and circuits are dried and cured thoroughly by passing them through tunnels and ovens.

Graphic overlays are embossed for keys and LED windows according to customer specifications, with key heights of up to 1.5mm. Additional processes include:

Punching

Connector assembly

Semi-finished and finished product assembly

Optical and electronic products are assembled in a 1,000-class cleanroom. Services also include OCA full lamination processing.

Final product shaping is achieved using automated die-cutting and high-precision cutting machines. Every step of production undergoes 100% appearance and functional inspection.

Products are sampled for:

Life testing

High and low-temperature testing

Salt spray testing

These ensure product durability and quality before shipping.

Approved products are packaged using anti-static inner packaging and export-grade outer boxes to ensure safe transportation. Products are continuously shipped from LuphiTouch's warehouses to clients worldwide.

LuphiTouch is committed to becoming a leading supplier of user interface products in China. If you need membrane switches, capacitive switches, touch display panels, rubber keypads, or other user interface products, please contact LuphiTouch®.

See you next time!